Low Density Packaging: What It Is and Why It Matters in Shipping and Storage

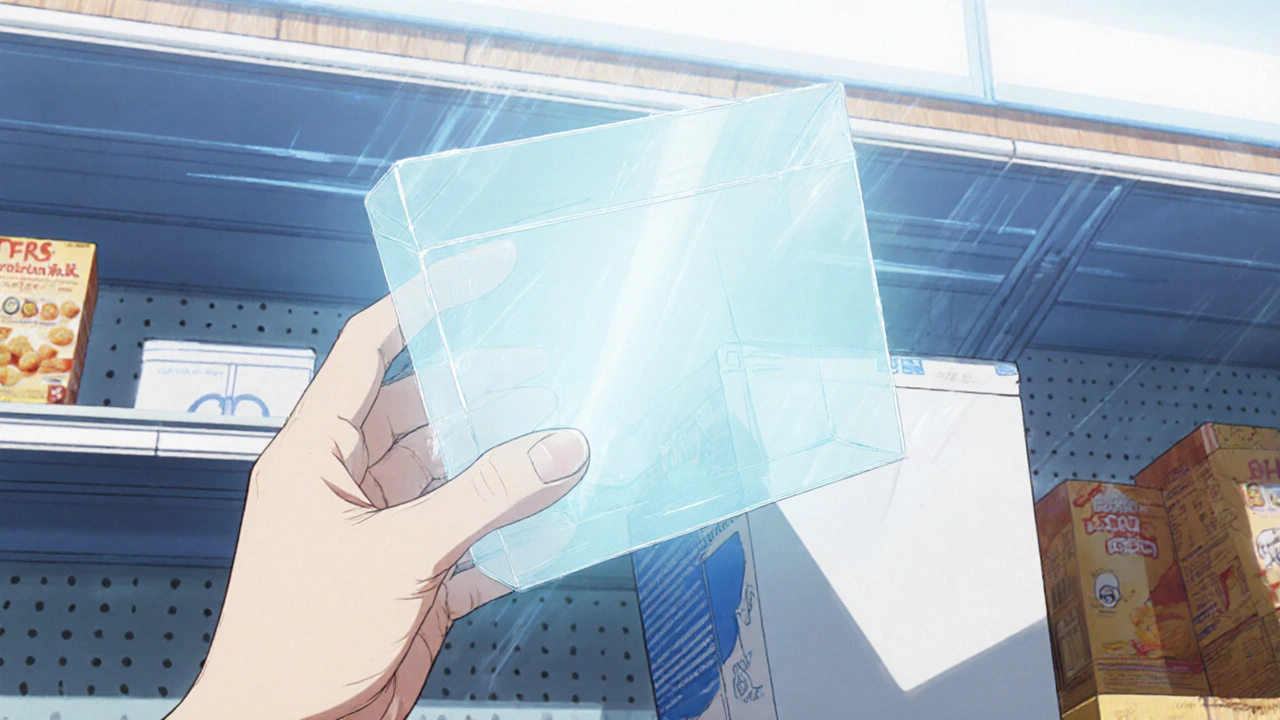

When you order something online and it arrives in a box that’s way bigger than the item inside, you’re seeing low density packaging, a type of packaging where the material takes up more space than the actual product it contains. Also known as bulk packaging, it’s common in e-commerce, pharmaceuticals, and retail shipping. It’s not always a mistake—it’s often used to protect fragile items, meet safety standards, or fit automated sorting systems. But it comes with a hidden cost: more fuel, more warehouse space, and more waste.

Why does this matter? Because packaging materials, the substances used to wrap, cushion, or contain products during transport like air pillows, foam inserts, and oversized cardboard boxes directly affect how many items fit on a truck or in a warehouse. A single pallet of low density packages might hold 30% fewer items than one with compact packaging. That means more trips, higher emissions, and higher prices for you. Even shipping efficiency, how well goods move through logistics networks with minimal wasted space or time suffers when packages are bloated. Companies that optimize packaging don’t just save money—they cut down on carbon footprints and reduce landfill waste.

It’s not just about size. Some products, like pills, powders, or medical devices, need extra cushioning by law or safety standards. But too often, the same packaging is used regardless of the product’s actual needs. That’s where smarter choices come in. Better design, right-sized boxes, and alternative materials like molded pulp or recycled air cushions can shrink the footprint without risking damage. You’ve probably noticed some brands now use smaller, sleeker boxes—those aren’t just trendy. They’re the result of real improvements in storage solutions, methods and systems designed to maximize space and minimize waste in warehouses and distribution centers.

What you’ll find below are real examples from people who’ve dealt with this issue firsthand—from patients getting medications in oversized boxes to businesses trying to cut shipping costs without sacrificing safety. These posts don’t just complain. They show what works, what doesn’t, and how small changes add up to big savings. Whether you’re shipping pills, supplements, or everyday goods, understanding low density packaging helps you make smarter choices—not just as a consumer, but as someone who cares about how things move through the world.