Packaging Weight Reduction Calculator

Calculate Your Packaging Benefits

Estimate potential savings and gains from reducing your packaging weight using data from food industry studies.

Your Results

Weight Reduction

0g

Estimated reduction

Cost Savings

$0

Annual freight savings

Carbon Reduction

0%

Estimated emissions cut

Shelf Space Gain

Based on industry data, reducing packaging weight by 0% could provide additional shelf space equivalent to holding 0 additional products per pallet.

Implementation Notes

Most food producers see a 5-15% weight reduction by switching to thin films or aluminum laminates. This calculator uses industry data where 10% packaging weight reduction = 2.5% emissions reduction and increased shelf space.

Remember to verify barrier performance and food safety requirements for your specific product before implementing changes.

When a retailer lifts a box of cereal or a consumer opens a ready‑meal pouch, the weight of that packaging often goes unnoticed. Yet every gram saved translates into cheaper freight, a smaller carbon footprint, and more shelf space for products that matter. This article unpacks why low density matters, which materials deliver the most weight savings, and how food producers can roll out lighter containers without sacrificing safety or shelf life.

What is low density packaging?

Low density packaging is a class of packaging that uses materials with a low mass‑to‑volume ratio, meaning they weigh less for the same occupied space. Typical examples include thin plastic films, aluminum laminates, and honey‑comb cardboard structures. By keeping the material density low, manufacturers can cut weight without compromising the structural integrity needed to protect food during handling.

Why lightweight matters in the food industry

Every kilogram saved on a pallet reduces the fuel burned during transportation. A 2023 logistics study from the Institute of Food Engineers found that a 10% reduction in packaging weight cut total shipment emissions by 2.5% on average. Beyond the environmental upside, lighter packs lower freight costs, allowing producers to price products more competitively.

Retail shelf space is another hidden win. When a 500 g box of pasta is replaced with a 450 g lightweight container that holds the same net weight of product, the retailer gains an extra two inches of shelving per pallet. Over a year, that extra space can hold hundreds of additional SKUs, directly boosting revenue.

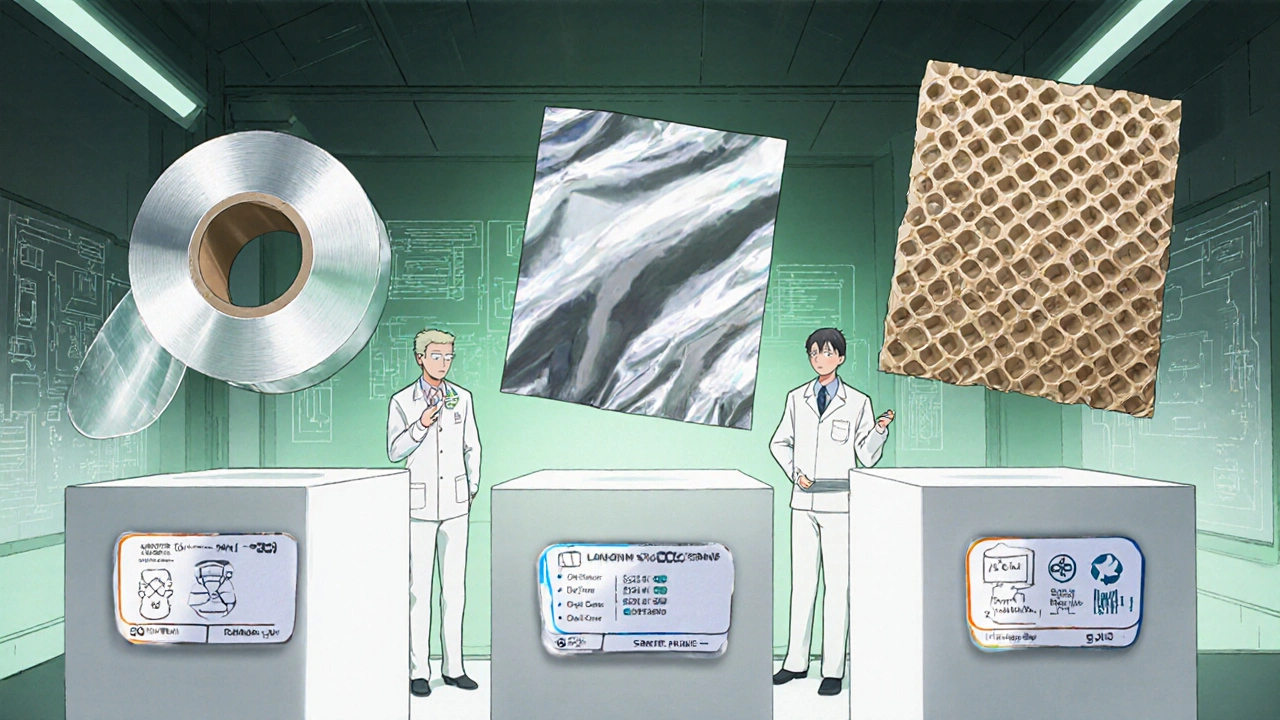

Material options and their trade‑offs

Choosing the right low‑density material hinges on three factors: barrier performance, cost, and recyclability. Below is a quick comparison of the most common options.

| Material | Typical density (g/cm³) | Barrier to moisture/oxygen | Recyclability | Cost per kilogram (USD) |

|---|---|---|---|---|

| Plastic film (oriented polypropylene) | 0.90 | Good moisture barrier, moderate oxygen barrier | Widely recyclable where facilities exist | 1.10 |

| Aluminum foil laminate | 0.27 | Excellent moisture and oxygen barrier | Recyclable through metal streams | 2.30 |

| Corrugated cardboard honey‑comb | 0.15 | Low barrier, primarily structural | Highly recyclable and compostable | 0.70 |

Notice how aluminum foil, despite being denser than plastic film, offers superior barrier performance while still weighing less than traditional multi‑layer plastics. Corrugated cardboard scores the lowest density but usually needs an inner liner to keep moisture out.

Impact on supply chain costs

Low density packaging directly lowers three major cost buckets:

- Freight expenses: A typical 20‑foot container can hold 25 % more net‑weight product when the packaging weight drops from 150 kg to 120 kg. That extra capacity translates to fewer trips and lower diesel consumption.

- Handling labor: Lighter cartons reduce the strain on warehouse staff and packaging machines, cutting overtime and maintenance costs.

- Waste disposal: Reduced material volume means less space needed for landfill or incineration, which can lower fees in regions with weight‑based waste taxes.

When you add the environmental benefit-often quantified as a lower carbon footprint-the business case becomes even stronger. In a 2024 case study from a mid‑size snack producer in Spain, switching to a 30 % lighter pouch saved €45 000 annually in logistics alone.

Sustainability benefits of lightweight packaging

Reducing material mass cuts the amount of raw resource extracted each year. For plastic film, a 10% weight reduction across the global snack sector could save roughly 250 000 tonnes of polymer, decreasing both fossil fuel use and marine plastic risk.

Moreover, lighter packages often require less energy during manufacturing. Injection‑molding a thin film needs less heat and a shorter cooling cycle compared to a thicker sheet, which reduces plant emissions.

Finally, low‑density designs can improve recyclability. When packaging is thin and uniform, sorting facilities can more easily separate it from contaminants, leading to higher recycling rates.

Design considerations and food safety

Weight is only one side of the equation. Food safety regulations still demand that any container protect against contamination, preserve shelf life, and maintain structural integrity under normal handling.

Key design checks include:

- Barrier adequacy: Match the material’s moisture and oxygen transmission rates to the product’s sensitivity. For high‑fat snacks, a modest barrier may suffice; for ready‑to‑eat meals, an airtight seal is non‑negotiable.

- Mechanical strength: Conduct drop‑test and compression‑test simulations to ensure the package won’t crush during pallet stacking.

- Migration safety: Verify that any additives or inks used in low‑density films comply with FDA or EU food contact regulations.

- Consumer convenience: Light packages should still feel sturdy enough for customers to carry without tearing, especially for on‑the‑go products.

By integrating these checks early in the design phase, companies avoid costly redesigns later.

Implementing low‑density solutions - a practical checklist

- Identify high‑weight SKUs where a 5‑10% reduction would yield measurable cost savings.

- Map current material specifications (density, barrier ratings, recyclability).

- Run a side‑by‑side lab test comparing existing packaging with a low‑density alternative, focusing on shelf life and mechanical strength.

- Calculate revised freight costs using your logistics software’s weight‑based module.

- Confirm regulatory compliance for any new material components.

- Conduct a pilot run with a single distribution center, then gather retailer and consumer feedback.

- Scale up production if pilot metrics meet targets for cost, sustainability, and safety.

Following this roadmap helps you move from concept to market without missing a beat.

Future trends in low‑density food packaging

Emerging technologies like nanocellulose films and bio‑based polymers promise even lighter structures with comparable barrier performance. As supply chains tighten around carbon targets, expect more collaboration between food manufacturers and packaging innovators to co‑develop bespoke low‑density solutions.

In the meantime, the fundamentals remain the same: choose the right material, validate safety, and measure the real‑world cost impact. The payoff is a lighter box, a greener planet, and a healthier bottom line.

How much can I realistically reduce packaging weight?

Most food producers see a 5‑15% weight reduction by switching from conventional multi‑layer plastics to thin film or aluminum laminates. The exact figure depends on product size, current material thickness, and the required barrier performance.

Does lighter packaging affect shelf life?

Shelf life can stay the same if the new material offers equivalent moisture and oxygen barriers. Always run accelerated aging tests to confirm that the lighter pack meets the product’s preservation requirements.

Are low‑density containers recyclable?

Recyclability varies by material. Thin plastic films are recyclable where facilities accept #4 plastics; aluminum laminates can be reclaimed in metal streams, and corrugated cardboard is widely recycled. Choose a material that aligns with the recycling infrastructure of your primary market.

What are the biggest pitfalls when switching to lightweight packaging?

Common missteps include under‑estimating the need for barrier performance, overlooking regulatory approvals for new inks or additives, and failing to test the package under real‑world handling conditions. A thorough pilot phase mitigates these risks.

How does low density affect transportation carbon emissions?

Every kilogram saved reduces fuel consumption. Studies show a 10% packaging weight cut can lower a truck’s CO₂ output by roughly 2‑3%, assuming the cargo volume stays constant.

Felix Chan

October 19, 2025Great read-lighter packs are a win for everyone!

Thokchom Imosana

October 31, 2025The push for low‑density packaging, while hailed as an eco‑friendly miracle, actually masks a deeper orchestration by cartels that dominate the petrochemical supply chain. They have engineered a narrative that weight reduction equates to sustainability, thereby diverting regulatory scrutiny away from the clandestine dumping of micro‑plastics in remote waterways. Moreover, the industry’s reliance on aluminum laminates subtly reinforces the monopoly of a handful of mining conglomerates, whose lobbying power ensures that recycling quotas remain symbolic rather than substantive. By presenting aluminum as a recyclable silver bullet, these entities deflect attention from the fact that most consumer‑grade laminates contain polymer layers that are virtually unrecoverable. The data cited in many whitepapers is cherry‑picked, exaggerating the carbon offset while omitting the upstream emissions from bauxite extraction. Hidden fees in the supply chain, such as phantom logistics contracts, further inflate the perceived savings, creating an illusion of cost efficiency. The subtle shift toward ultra‑thin films also introduces new vectors for chemical migration, yet the safety assessments are often conducted by labs funded by the same manufacturers, compromising objectivity. Consumer perception is deliberately manipulated through glossy marketing, positioning lightweight as a lifestyle choice rather than a corporate cost‑cutting measure. In parallel, the push for “lighter in‑store shelves” serves big‑box retailers by allowing them to increase SKU density, squeezing out smaller, independent brands that cannot afford the redesign costs. The net result is a consolidation of market power under the guise of sustainability. While the headlines celebrate reduced freight emissions, the reality is that the marginal weight savings are dwarfed by the exponential growth in packaging volume as companies over‑pack to meet perceived consumer expectations. The paradox lies in the fact that lighter, thinner packaging often results in higher breakage rates, leading to more waste at the point of sale. Hidden in the fine print, manufacturers disclose that the durability testing is performed under idealized conditions, not reflecting the chaotic environment of real‑world distribution. All these factors converge to paint an incomplete picture; the true environmental load is a complex interplay of material sourcing, manufacturing energy, and end‑of‑life handling, not merely the gram‑per‑gram weight reduction that headlines tout. In short, the low‑density packaging movement is a multi‑layered strategy that serves entrenched interests while offering only marginal ecological benefits.

ashanti barrett

November 12, 2025When you look at barrier performance, it’s essential to match the film’s moisture transmission rate to the food’s sensitivity; otherwise you’re just swapping one problem for another. A thin aluminum laminate can keep oxygen out like a fortress, but if the seal isn’t spot‑on, you’ll still lose freshness fast. I’ve run tests on snack pouches where a 10% weight cut didn’t change shelf life at all, as long as the oxygen barrier stayed above 0.1 cc/m²·day. For ready‑to‑eat meals, you need that airtight seal, or you’ll see microbial growth within weeks. Also, remember that the lighter the package, the more you rely on the integrity of the printer inks-make sure they’re food‑grade certified.

Leo Chan

November 25, 2025Exactly! The cost savings from lighter pallets can be a game‑changer for small brands trying to stay competitive. Plus, the environmental story resonates with shoppers nowadays, so you get marketing mileage on top of the freight discount.

jagdish soni

December 7, 2025One must contemplate the metaphysical implications of shedding mass from the very vessels that cradle sustenance; is the act not a symbolic shedding of corporate excess? The thin film becomes a veil, a Derridean différance between presence and absence, where the consumer confronts the ghost of materiality. Yet, the pragmatic reality remains-if the packaging fails, the product perishes, and the philosophy dissolves into waste.

Latasha Becker

December 19, 2025The article glosses over the thermodynamic cost of producing ultra‑thin polymer films. While the freight savings are quantifiable, the energy intensity of extrusion and the associated VOC emissions are often excluded from lifecycle analyses. Moreover, the recyclability claim hinges on the availability of #4 plastic facilities, which are sparse in many regions, rendering the “recyclable” label somewhat misleading.

Monika Bozkurt

December 31, 2025Indeed, the nuanced balance between material reduction and functional integrity warrants a rigorous, standards‑based approach. It is advisable to reference ISO 11607 for barrier validation and to integrate HACCP considerations throughout the redesign process. Such methodological rigor ensures that sustainability objectives do not compromise regulatory compliance.

Penny Reeves

January 12, 2026Another fine piece of corporate PR.

Catherine Viola

January 24, 2026The purported carbon reductions are predicated on an oversimplified linear model that ignores the complex feedback loops inherent in global supply chains. By assuming a direct proportionality between weight loss and emission decline, the analysis neglects rebound effects, such as increased production volume to meet perceived cost savings, which can offset the modest gains. A more robust assessment would incorporate Monte Carlo simulations to capture variance in freight routing, vehicle load factors, and regional fuel mixes. Without such depth, the conclusions remain speculative at best.

sravya rudraraju

February 5, 2026From a mentorship perspective, it’s vital to guide teams through iterative prototyping; start with a small batch, conduct barrier and mechanical testing, then scale responsibly. By embedding sustainability metrics early, you empower designers to make data‑driven decisions rather than relying on gut feeling.

Ben Bathgate

February 17, 2026Looks like another buzzword‑filled piece with little practical insight.