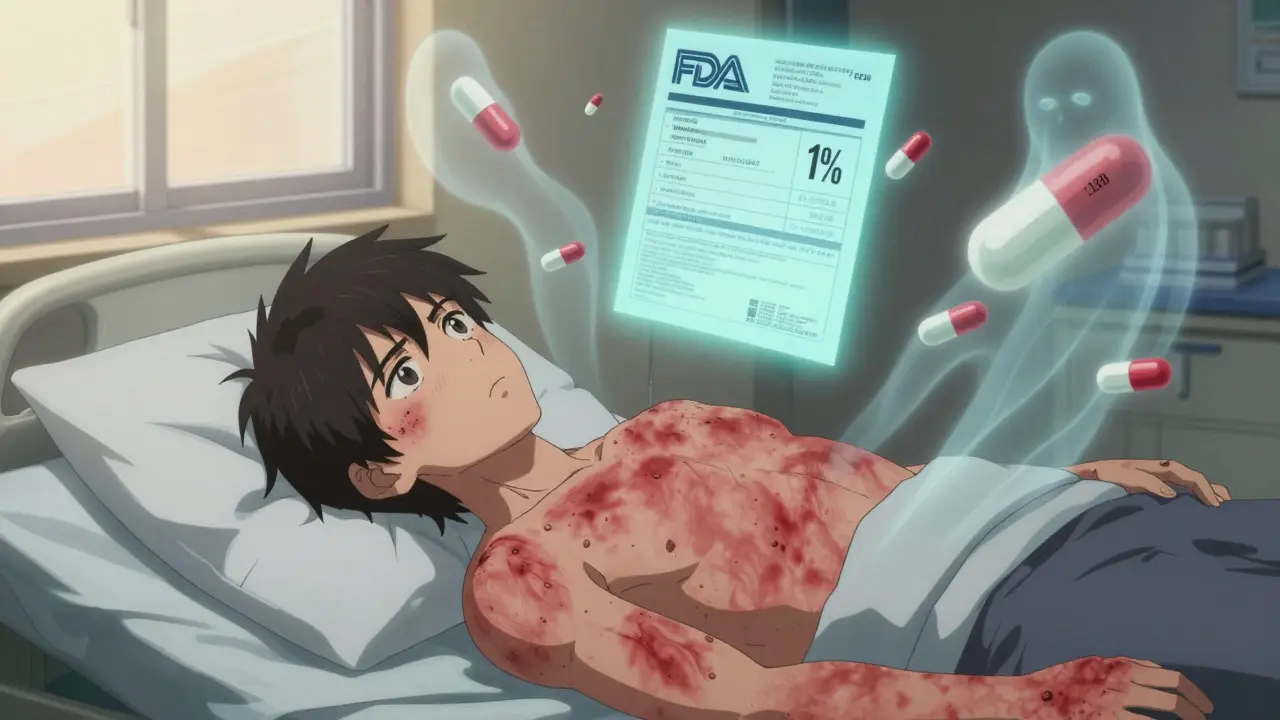

When you pick up a generic pill from the pharmacy, you expect it to work just like the brand-name version-same active ingredient, same dose, same effect. But what if that pill isn’t just ineffective? What if it’s contaminated? Between 2020 and 2022, over 1,200 reports of potential contamination in generic drugs were filed with the FDA. Some led to serious harm-rashes, infections, even organ damage. The truth is, contamination isn’t rare. It’s a growing risk tied to how these drugs are made, shipped, and tested.

What Exactly Is Drug Contamination?

Contamination means unwanted substances get into your medicine. This could be leftover chemicals from another drug made on the same machine, bacteria from dirty equipment, or even tiny metal particles from worn-out tools. The FDA defines it as the accidental introduction of impurities-chemical, microbial, or physical-into a drug product. It’s not about fake pills. It’s about real drugs that got dirty during production. The biggest culprits? Cross-contamination and microbial growth. Cross-contamination happens when residue from one drug sticks to equipment and ends up in the next batch. For example, a machine that made a blood thinner might not be cleaned well enough before making a diabetes pill. Even a few parts per million of the wrong chemical can cause dangerous reactions in sensitive patients. Microbial contamination is just as serious. Oral pills can’t have more than 1,000 colony-forming units (CFU) of bacteria per gram. Yeast and mold? No more than 100 CFU. If those numbers are higher, the drug could cause infections-especially in people with weak immune systems.Why Are Generic Drugs More at Risk?

All drugs-brand or generic-must meet the same FDA standards. But the system they operate under is different. Generic manufacturers often work with razor-thin profit margins-around 20-25% compared to 60-70% for brand-name companies. That means less money for clean rooms, better equipment, or advanced testing. Over 80% of the active ingredients in U.S. drugs come from just two countries: India and China. In 2022, FDA inspections found that 12.7% of Indian manufacturing facilities had contamination-related issues-more than double the rate in U.S.-based plants. Older factories, built before 2000, are 34% more likely to have contamination problems because their ventilation, airflow, and cleaning systems don’t meet modern standards. Even cleaning protocols can fall short. The FDA says manufacturers must remove at least 10 parts per million (ppm) of previous drug residue. But for powerful drugs-like cancer treatments or hormone therapies-that limit might be too high. Experts say acceptance criteria should be tailored to each drug, not set at a one-size-fits-all number.How Contamination Happens: The Real-World Pathways

It’s not just about dirty machines. Human error plays a huge role. In cleanrooms, one person sheds about 40,000 skin cells per minute-and generates 100,000 tiny particles every time they stand still. That’s why staff must wear full gowns, masks, and gloves. But training isn’t always consistent. A 2022 study found that 75-80% of particles in pharmaceutical environments come from people. Then there’s the physical handling of drugs. Piercing a vial’s rubber stopper with a needle causes contamination in 62% of hazardous drug incidents. Pulling the needle out? Another 41%. Breaking glass ampules? That’s 28%. These aren’t just pharmacy myths-they’re documented risks. Even the cleaning agents matter. If a cleaner doesn’t kill spores, bacteria can hide and grow. The FDA and USP now require disinfectants to be sporicidal, meaning they must destroy bacterial and fungal spores. But many facilities still use outdated solutions that don’t cut it.

What’s Being Done to Prevent It?

The good news? Many manufacturers are upgrading. Teva’s facility in Bologna, Italy cut cross-contamination by 78% between 2018 and 2022 by switching to closed manufacturing systems-where drugs are made in sealed, automated units, not open tables. Mylan’s Morgantown plant reduced contamination by 82% using real-time particle monitors that alert staff the moment air quality drops. New tech is making a difference. Rapid microbiological methods can detect contamination in 4 hours instead of 7 days. By 2022, 63% of top generic makers had adopted these tools. The FDA’s new PREDICT system now flags 37% more suspicious shipments at the border than before. And starting January 1, 2023, every sartan-class drug (like valsartan) must be tested for nitrosamine impurities-a direct response to the 2018-2019 global recall crisis that affected over 2,000 products. Facilities are also investing in better design. New plants must meet ISO Class 8 standards for non-sterile drugs and ISO Class 5 for sterile ones. That means controlled airflow, positive pressure, and HEPA filters. These upgrades cost $2-5 million per facility-but they save millions in recalls.What Happens When Contamination Is Found?

When a contaminated batch is discovered, the manufacturer must recall it. Under FDA rules (21 CFR Part 7), recalls are classified by risk level: Class I (dangerous or life-threatening), Class II (temporary or reversible harm), and Class III (unlikely to cause harm). In 2022, 22% of all drug recalls were due to contamination-and 37% of those were generic drugs. The FDA’s MedWatch system lets patients and pharmacists report suspected contamination. Between 2020 and 2022, 387 reports linked contamination to actual harm. One patient developed severe dermatitis from a generic hydrocortisone cream contaminated with an unknown chemical. Another Reddit user, u/PharmTech99, spotted blue specks in metronidazole tablets-later confirmed to be copper particles. But here’s the problem: most pharmacists can’t test drugs themselves. A 2022 survey found that 63% of independent pharmacies lack the tools or budget to check for contamination. They rely on the manufacturer’s word-and the FDA’s inspection reports, which only cover 1% of imported drugs.

What You Can Do as a Patient or Pharmacist

You can’t test a pill at home. But you can stay alert.- Check for unusual appearance. If a pill looks different-new color, odd texture, specks, or odor-don’t take it. Report it to your pharmacist.

- Use the FDA’s MedWatch portal. If you or someone you know has a reaction that doesn’t match the drug’s known side effects, file a report. These reports help the FDA spot patterns.

- Ask your pharmacist about the manufacturer. Not all generics are made equal. Some companies have better track records. Ask if the drug comes from a facility with recent FDA inspections.

- Report suspicious batches. If multiple patients report the same issue with the same generic drug, it’s not coincidence. Tell your pharmacy and the FDA.

Jacob Cathro

January 20, 2026so like... generic pills are just russian roulette now? 🤡 i took my blood pressure med last week and felt like i swallowed a whole bag of glitter. no joke. my doctor just shrugged and said 'it's generic, what do you expect?' like i'm the crazy one for thinking my medicine shouldn't look like a crayon melted in a microwave. FDA? more like F*cked Again.

and don't even get me started on the 'manufacturers upgrading' bs. you think teva gives a damn? they're busy counting cash while grandma in ohio gets a rash from her 'same active ingredient' pill. capitalism wins again. again.

Paul Barnes

January 21, 2026The article accurately details the systemic failures in pharmaceutical manufacturing oversight, particularly with regard to cross-contamination and microbial thresholds. The FDA’s 1% inspection rate of imported products is statistically indefensible, and the reliance on self-reported data from manufacturers creates an unacceptable risk profile for consumers. The 2022 data indicating that 37% of contamination-related recalls involved generic drugs is not an anomaly-it is a predictable outcome of profit-driven regulatory arbitrage.

pragya mishra

January 21, 2026As someone from India, I’m sick of being blamed. Yes, some factories cut corners-but you think US plants are clean? My cousin works in a pharma lab in Hyderabad. They follow WHO-GMP, wear full PPE, and test every batch. But the FDA doesn’t care where it’s made-they just want to scare Americans into buying expensive brand names. You want safety? Pay more. Or stop pretending this is about health and not about profit.

Manoj Kumar Billigunta

January 22, 2026It’s easy to panic about contamination, but let’s not forget why generics exist. They save lives by making medicine affordable. A diabetic in rural Texas can’t afford $500 insulin. They need the $4 generic. The problem isn’t generics-it’s underfunded oversight and global supply chain gaps.

Patients should report odd-looking pills. Pharmacists should log batch numbers. Companies should invest in real-time monitoring. And regulators? They need more funding, not more blame. We can fix this without throwing out the system that keeps millions alive.

It’s not perfect, but it’s better than nothing. Let’s push for better, not fear.

sagar sanadi

January 22, 2026contamination? sure. but did you know the FDA approves pills that have 10ppm of a cancer drug in your blood pressure pill? that’s not contamination-that’s policy. they let it happen on purpose because they don’t want to shut down 80% of the world’s supply.

and the 'new tech'? yeah right. the same people who approved the fake vials in 2019 are now selling you 'AI-powered predictions.' like that’s gonna stop a guy in a dirty factory in Bangalore from sneezing into a vial.

the real answer? stop buying generics. go to mexico. buy the real stuff. cheaper anyway.

kumar kc

January 23, 2026People die because of this. Stop making excuses. The system is broken. End of story.

Carolyn Rose Meszaros

January 25, 2026my mom took a generic thyroid med last year and started having panic attacks-like, full-on shaking and crying. she thought it was stress. turns out, the pill had traces of a beta blocker. she didn’t even know she was allergic to it.

now she only buys the brand name. it costs 3x more, but she sleeps at night. i just wish the pharmacy had told her the manufacturer was the one with the 2021 recall.

also-blue specks?? that’s wild. i’m gonna check my metronidazole tonight 😳

Greg Robertson

January 25, 2026Just wanted to say thanks for laying this out so clearly. I’m a pharmacy tech and we get these generics every day. We don’t test them, we just dispense. It’s scary knowing we might be handing out something dangerous and having zero way to know.

But I do check the lot numbers when people report weird stuff. Last month, two people came in with the same generic metformin that had a weird smell. We flagged it, and sure enough-FDA issued a recall two days later.

So yeah, we’re powerless... but we’re not silent. Keep reporting. It matters.

Nadia Watson

January 26, 2026As a former regulatory affairs specialist in the pharmaceutical industry, I can confirm that the challenges described are systemic and deeply entrenched. The notion that 'all drugs must meet the same standards' is technically true-but compliance is enforced unevenly, especially across international borders.

Facilities in low-resource nations often lack the capital to retrofit aging infrastructure. Meanwhile, the FDA's inspectional resources have not scaled proportionally with the volume of imports. The result is a regulatory gap that is not a failure of intent, but of capacity.

That said, the rise of rapid microbiological testing and closed-system manufacturing is promising. The real obstacle is not technology-it is political will and sustained funding. Without both, even the most advanced systems will remain underutilized.

Patients should absolutely report anomalies. But we must also demand that our legislators prioritize funding for global pharmaceutical oversight-not just domestic inspections.

And yes, I misspelled 'proportionally' above. Apologies.